Plastic pallets have become an indispensable part of modern logistics and material handling operations. Their versatility, durability, and cost-effectiveness have made them the preferred choice for businesses worldwide. In this comprehensive guide, we delve into the world of plastic pallets, exploring their history, types, benefits, and applications.

A Brief History of Plastic Pallets

The origins of plastic pallets can be traced back to the early 20th century when the first wooden pallets were being introduced to streamline material handling. However, wooden pallets faced limitations in terms of durability and weight restrictions. In the 1950s, with the advent of high-density polyethylene (HDPE), plastic pallets emerged as a viable alternative.

HDPE offered significant advantages over wood, including:

- Durability: Plastic pallets could withstand harsh environments, heavy loads, and repeated use without warping or cracking.

- Weight: Plastic pallets were significantly lighter than wooden pallets, reducing transportation costs and improving overall efficiency.

- Hygiene: Plastic pallets could be easily cleaned and sanitized, making them ideal for food and pharmaceutical applications.

As a result of these benefits, plastic pallets quickly gained popularity, becoming the industry standard for material handling.

Types of Plastic Pallets

Plastic pallets come in a variety of sizes, designs, and load capacities to cater to diverse applications. Some of the most common types of plastic pallets include:

- Euro Pallets: These are the most widely used plastic pallets globally, measuring 1200 x 800 mm (47.2 x 31.5 inches) and designed to fit standard shipping containers.

- ISO Pallets: These pallets adhere to the International Organization for Standardization (ISO) specifications, measuring 1100 x 1100 mm (43.3 x 43.3 inches), and are particularly common in Asia.

- Two-Way Entry Pallets: These pallets have forklift entry points on two sides, making them suitable for maneuvering in tight spaces.

- Four-Way Entry Pallets: These pallets have forklift entry points on all four sides, offering maximum flexibility for loading and unloading.

- Rackable Pallets: These pallets are designed for use in pallet rack systems, allowing for efficient storage and retrieval of goods.

Benefits of Using Plastic Pallets

Plastic pallets offer a multitude of benefits over traditional wooden pallets, making them the preferred choice for many businesses:

- Durability: Plastic pallets are resistant to moisture, rot, and insects, ensuring long-lasting performance in various environments.

- Weight: Plastic pallets are significantly lighter than wooden pallets, reducing transportation costs and improving fuel efficiency.

- Load Capacity: Plastic pallets can withstand heavy loads without warping or cracking, making them suitable for a wide range of applications.

- Hygiene: Plastic pallets are easy to clean and sanitize, making them ideal for food and pharmaceutical industries.

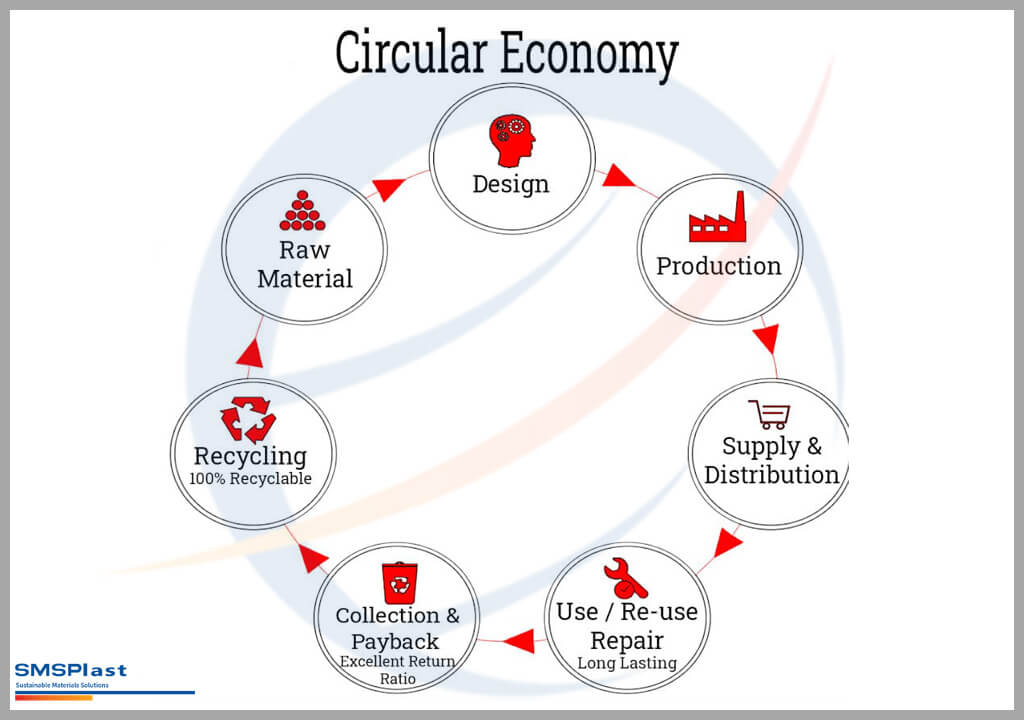

- Environmental Friendliness: Plastic pallets can be recycled, reducing their environmental impact compared to wooden pallets.

Applications of Plastic Pallets

Plastic pallets are used extensively in various industries and applications, including:

- Warehousing and Storage: Plastic pallets are widely used for storing goods in warehouses and distribution centers, maximizing space utilization and optimizing inventory management.

- Shipping and Transportation: Plastic pallets are essential for transporting goods via trucks, rail, and ships, ensuring secure and efficient movement of materials.

- Manufacturing and Production: Plastic pallets are used in manufacturing facilities to move components, products, and raw materials throughout the production process.

- Retail and Distribution: Plastic pallets are used in retail stores and distribution centers to display and transport merchandise, facilitating smooth inventory management and product flow.

- Agriculture and Farming: Plastic pallets are used in agricultural operations to transport produce, seeds, and fertilizers, ensuring efficient handling and preventing damage.

Conclusion

Plastic pallets have revolutionized material handling operations worldwide, offering a versatile, durable, and cost-effective solution. Their ability to withstand harsh environments, carry heavy loads, and adapt to various applications has made them indispensable in industries ranging from manufacturing to logistics and retail. As businesses continue to seek sustainable and efficient solutions, plastic pallets are poised to play an even more significant role in the future of material handling.

agricultural baskets

agricultural baskets Plastic pallets

Plastic pallets Industrial baskets

Industrial baskets large containers plastic

large containers plastic Slaughterhouse and poultry baskets

Slaughterhouse and poultry baskets Dairy baskets

Dairy baskets