At SMSPlast, we are committed to responsible manufacturing and environmental stewardship. Plastics are a valuable resource, but plastic waste poses a significant challenge. That’s why plastic recycling is a core part of our sustainability efforts. This article will delve into the world of plastic recycling, explain the different processes involved, and highlight SMSPlast’s dedication to a greener future.

The Ever-Present Plastic: A Material and a Responsibility

Plastics are a diverse group of polymeric materials with countless applications in our daily lives. Their lightweight nature, durability, and versatility make them ideal for various products, from packaging and medical equipment to automotive parts and electronics. However, the very properties that make plastics so useful also contribute to plastic pollution. Traditional plastics are non-biodegradable, meaning they can persist in the environment for hundreds of years, causing harm to wildlife and ecosystems.

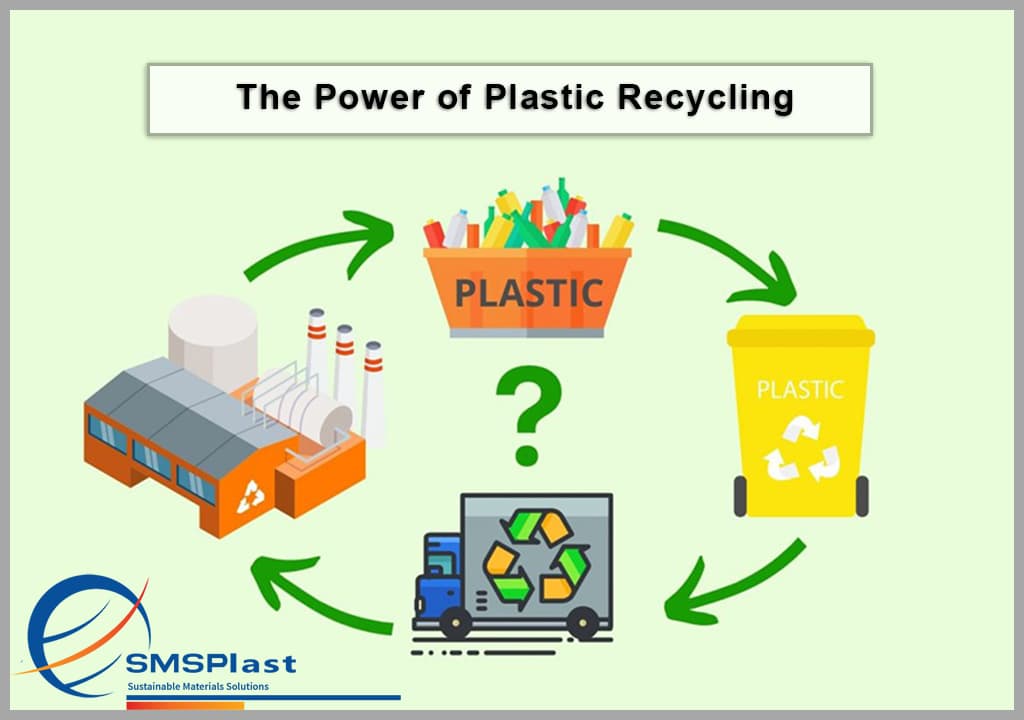

The Power of Recycling: Reducing Our Environmental Footprint

Plastic recycling offers a powerful solution to plastic waste management. By recycling plastic materials, we can:

Reduce reliance on virgin plastic production: Recycling existing plastic lessens the demand for new plastic production, which in turn reduces our dependence on fossil fuels and lowers greenhouse gas emissions.

Conserve resources: Recycling plastic conserves valuable natural resources like oil and gas, which are finite and essential for various industries.

Minimize landfill waste: Diverting plastic waste from landfills reduces the environmental impact of overflowing landfills, including methane emissions and potential soil and water contamination.

Understanding the Nuances: Types of Plastic Recycling

There are three primary methods for recycling plastic:

Mechanical Recycling: The most common method, mechanical recycling involves sorting, cleaning, shredding, and melting plastic waste into flakes or pellets. These pellets can then be used to manufacture new plastic products.

Chemical Recycling: This method breaks down plastic waste into its chemical building blocks using various techniques like pyrolysis or solvolysis. These chemicals can then be used to create new virgin-quality plastics.

Energy Recovery: While not technically recycling, energy recovery involves burning plastic waste to generate heat or electricity. This method is typically used when mechanical or chemical recycling is not feasible.

The Art and Science Behind Plastic Recycling: A Step-by-Step Look

The specific steps involved in plastic recycling can vary depending on the facility and the type of plastic being processed. However, a general process often includes:

Collection and Sorting: Plastic waste is collected from various sources and meticulously sorted by type (e.g., PET, PP, PVC) to ensure compatibility during processing.

Cleaning and Washing: Contaminants like dirt, food residues, and labels are removed through washing processes.

Shredding and Grinding: The sorted plastic is shredded or ground into small flakes or pellets.

Melting and Granulation: The plastic flakes or pellets are melted and extruded into uniform granules for use in new plastic products.

SMSPlast: Champions of a Sustainable Future

At SMSPlast, we are dedicated to incorporating recycled materials into our manufacturing processes whenever possible. We actively partner with reputable recycling facilities to source high-quality recycled plastic feedstock. By integrating recycled content into our products, we are not only reducing our environmental footprint but also contributing to a circular economy for plastics.

Conclusion: Working Together for a Sustainable Future

Plastic recycling is a collaborative effort that requires the participation of manufacturers, consumers, and waste management companies. By understanding the importance of plastic recycling and making informed choices, we can all contribute to a more sustainable future. At SMSPlast, we are committed to playing our part and encourage you to join us on this crucial journey.

agricultural baskets

agricultural baskets Plastic pallets

Plastic pallets Industrial baskets

Industrial baskets large containers plastic

large containers plastic Slaughterhouse and poultry baskets

Slaughterhouse and poultry baskets Dairy baskets

Dairy baskets